Some post baby updates that

are car related

First off, I've lined up a truck and trailer to get my currently disassembled rx7 to my painter 2 hours away. This will be happening this Monday July 14th. After that it'll be up to him to make it pretty.

Secondly I had a member PM me earlier today asking for a status update on my master cylinder replacement. This work was completed a couple of weeks ago but I haven't had a chance to document it. Rather than reply to his PM individually I decided to get off my ass and do it properly.

For reference, this idea came from this thread:

http://www.norotors.com/index.php?topic=19151.0My reasoning for the thread above is that I really don't like the Wilwood MC option for LSX swaps. I don't like that there are countless stories of failure, I don't like that it's not clocked right for RX7's and it requires a crazy stupid adapter from hinson to get it right, I don't like that it's huge (in a place where space is an expensive commodity), I don't like that you have to adapt the rod to the FD's clevis (or tap the FD's clevis), and I don't like that it's expensive.

Before I get to it I just wanted to be clear that this is NOT a drop in replacement. I don't think that was expressed very well in the thread above so I wanted that to by crystal clear so no-one walked away from this with illusions of a plug and play part.

Finally, I went about this conversion without welding ANYTHING. Greg/Pez suggested welding the stock FD clevis to the M8x1.0 coupling nut. In retrospect that's the way to do it. Doing it my way required 3 painful adjustments to get my clutch pedal throw in its sweet spot.

With that being said, here's the part list:

$30.00 - Beck Arnley 072-8657 Clutch Master Cylinder - Amazon.com

$6.00 - Earl's 997517ERL Banjo Bolt with crush washers - Amazon.com

$10.00 - Earl's 997641 Steel -4 AN Banjo Adapter (

some folks may need -3 AN adapter based on what you used for your clutch line) - Amazon.com

$3.54 - Metric Class 5.8 Zinc-Plated Steel Coupling Nut, M8 Screw Size, 1.25 mm Pitch, 38MM Length, 16MM Width - 93355A105 - Mcmastercarr

$9.60 - 18-8 Stainless Steel Male-Male Thread Adapter, M8 X 1.25, 12.7 mm L, M8 X 1.0, 12.7MM L, 13MM Hex - 95316A880 - Mcmastercarr (only needed if you're

not welding)

$13.78 - High-Strength Zinc Yellow-Chromate Plated Cap Screw, Class 10.9 Steel, M8 Full Thread, Pitch: 1.25, 50MM LG (25 pack) - 90854A178 - Mcmastercarr

$8.45 - Class 8 Steel Nylon-Insert Hex Flange Locknut, Zinc-plated, M8 Size, 1.25mm Pitch, 13mm W, 11.1mm H (100 pack) - 92461A400 - Mcmastercarr

Total = $81.37 and if you've got boxes full of hardware you can probably get the cost down to $60 and not have to order 121 extra nuts & bolts from mcmaster carr

So what makes the Land Cruiser MC so great? Well, for starters, it's only going to cost $30 to replace if you ever have it die on you. That's $30 with a brand new reservoir and cap. It's small, it's clocked right, it's an OEM grade part with the reliability of a factory MC.

Here's what's challenging about swapping one of these in.

1. Even though the mounting ears are clocked right, the mounting holes are not spaced for a RX7. It requires that you get out your dremel and elongate the holes (pics below).

2. I had to modify my clutch pedal sheet metal with a dremel so that the inner section of the MC's body could slide through (pics below)

Additionally, if you don't weld the coupling nut to the FD's clevis you'll face the following challenges as well:3. The coupling nut has to be shortened

4. The M8x1.0 leg of the male-to-male thread adapter has to be shortened

5. The MC rod has to be shortened

Here's what we're dealing with:

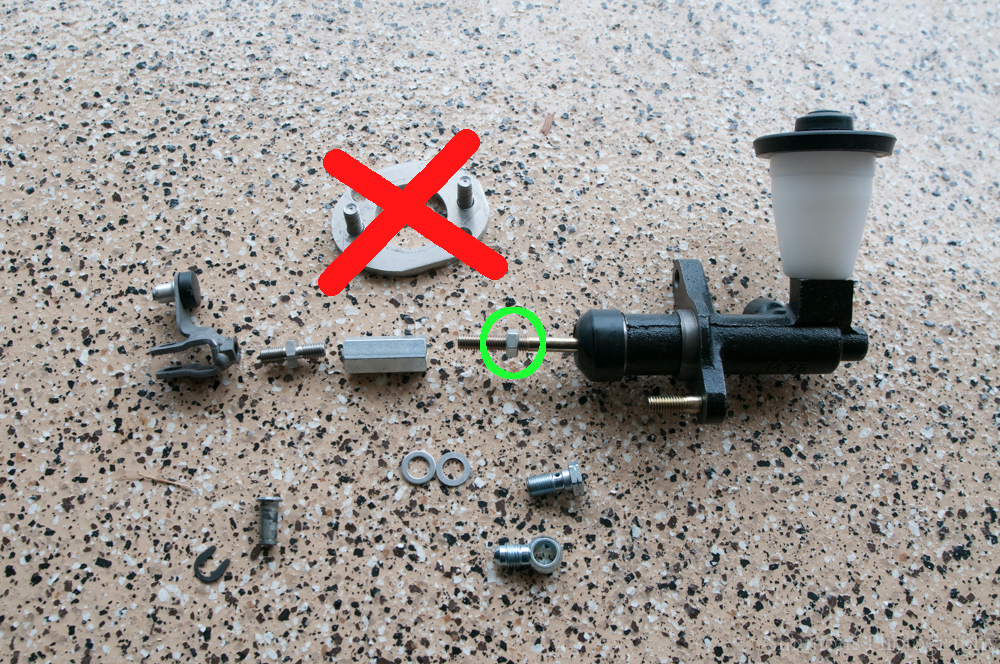

Just ignore the Hinson adapter crossed out in red. It somehow jumped into the picture even though it's not required. Also, in the pic above, the nut circled in green came with the MC and I simply screwed it all the way up on the rod (closest point of the rod to the MC) and red loc tite'd it so I'd have a nut to turn the rod for clutch adjustments (this is something else Greg/Pez recommended welding, but I think red loc-tite is fine for this purpose).

One thing that is not shown in the pic above is that if you are not welding the female coupler directly to the FD's clutch pedal clevis, you'll have to chop ~1/4" off of the end of the MC's rod.

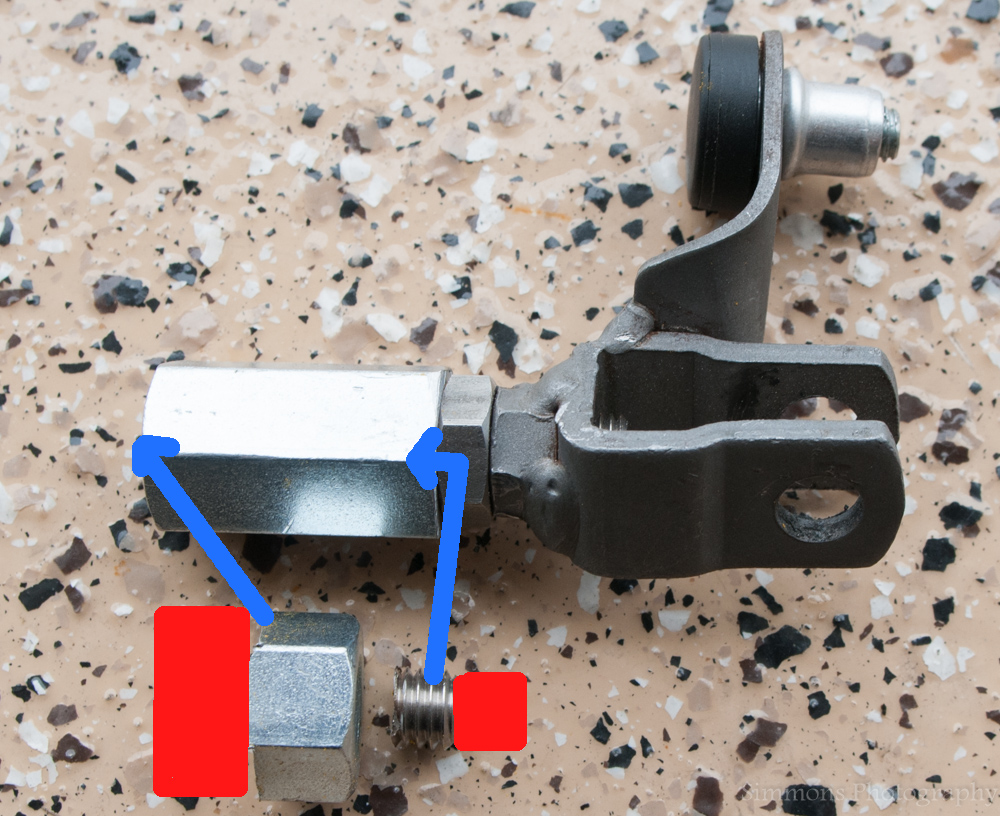

Here's one of the tricker parts for the way I did it (no welding). The pic above shows how I adapted the LandCruiser's M8x1.25 rod to the FD's M8x1.0 clevis. I used a M8x1.25 female coupler and a M8x1.25-to-M8x1.0 male-to-male adapter. This will go together exactly how it shows in the pic above and it'll thread right onto the LandCruiser MC rod. The problem is that it will end up too long for the FD's pedal throw. That's where the little cut pieces below the adapted piece come into place. This pic was taken 1/2 way though the adjustment process. The blocks of red indicate that I SHOULD have cut more off the respective female coupler and the male-to-male adapter (M8x1.25 side).

The red blocks show that I should have doubled what I originally trimmed.

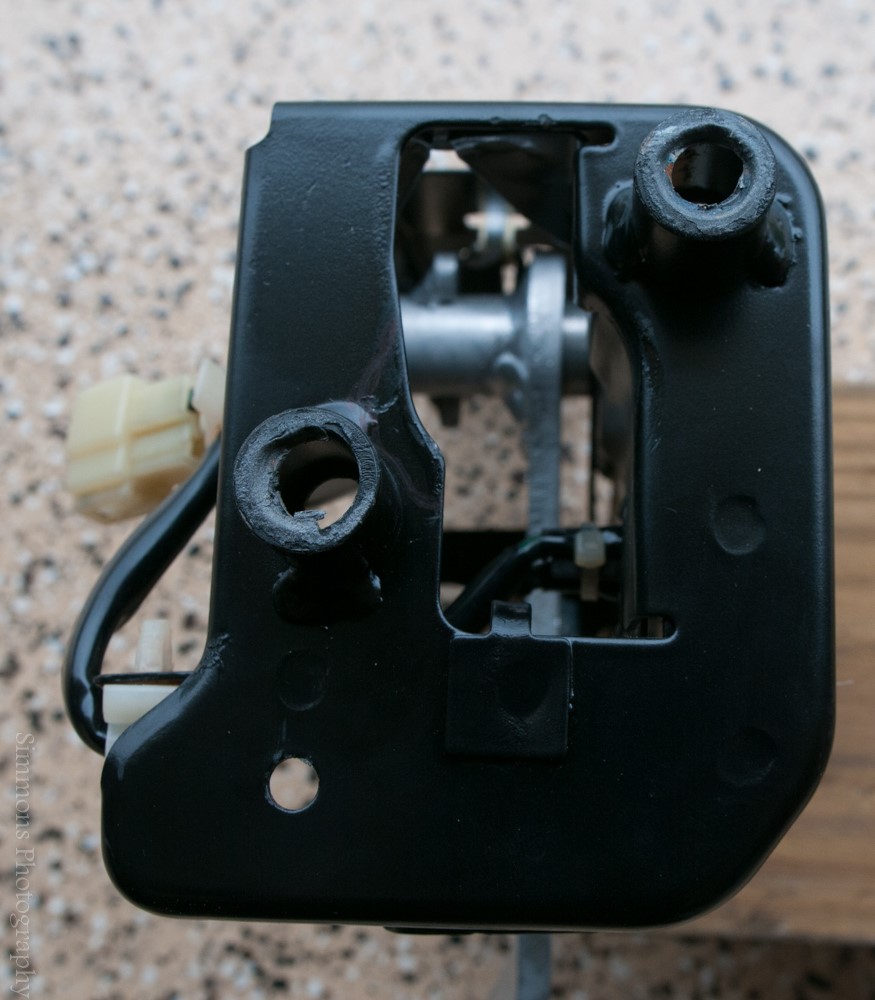

This pic shows how I elongated the MC's mounting holes with a dremel. You can get away with less trimming than I did.

The three pics above show the last modification I had to make. It shows the clutch pedal assembly before and after a quick dremel trim. The third picture shows how the trim created additional clearance so that the LandCruiser MC can fit through and into the pedal assembly.

That's pretty much it. For me it was a 2 weekend ordeal because I chose to try and do this without welding.

It's been working like a champ. After adjusting the clutch pedal throw it feels perfect and works like it was put on at the factory.

Lane