*Update* As of 8-9-16 I have sold off all my AC line build materials to mattster03. Matt is taking over the business so if you want to drink a cold beer while Matt builds your AC lines vs you spending hours building them via these instructions, you've got the option now. Message him

here if you're interested.

----------------------

As I step back from producing products for the RX7 community I wanted to turn over my designs and convert my projects into a more open source form. This is one of those projects.

Unlike my last DIY AC Line tutorial I am trying to make this tutorial more generic so perhaps the FC guys can get in on the fun. This is still very much geared towards FD owners as all of my build examples will be FD applications, but the parts discussed and theory are universal.

This is going to look intimidating. Itís a ton of information to process. There will be a good bit of you that will take one look at this and want to throw your hands up and curse me for discontinuing my line building service. For those people I would simply say that having someone build you a line kit doesnít get you out of this work haha! If you were to ask any one of my previous customers Iím sure theyíd tell you it was a pain in the ass to get me the data I needed to build their lines. Long story short, no-one, not me, not anyone else, can build a bespoke line kit without working out all the details to make a planÖ. Aaannd when that person is building lines remotely, guess who has to gather and understand all that data?

So in the end, it may look like big mountain to climb doing this yourself, but really, youíd be doing it anyway buying a kit from me and all you add by doing it all yourself is crimping it all together.

Do NOT simply skip down to the posted example lines kits below and pick out what you think will work for you and go to town. That is a shortcut to a bad time. Believe me. Do your due diligence and do it right the first time.

Terms of use Ė

I am releasing this information freely and you can do whatever you wish with it. All that I ask is that if you do post this information elsewhere, please provide a link back to this thread. As far as support goes, this thread is it. Please donít PM me with circuit specific or troubleshooting questions. If you have questions, post here and let the very capable community here work it out. If the question canít be answered by the community I will hop in and answer (Iím subscribed to this thread).

Ultimate AC Line Construction TutorialWelcome to revision 2 of my AC Line DIY tutorial. Iím going to divide this section into 6 parts:

1. System Identification

2. Component Level Considerations / Pre-Planning

3. Fittings, Seals, and Tools

4. Examples of line kits Iíve built

5. Installation

6. Charging

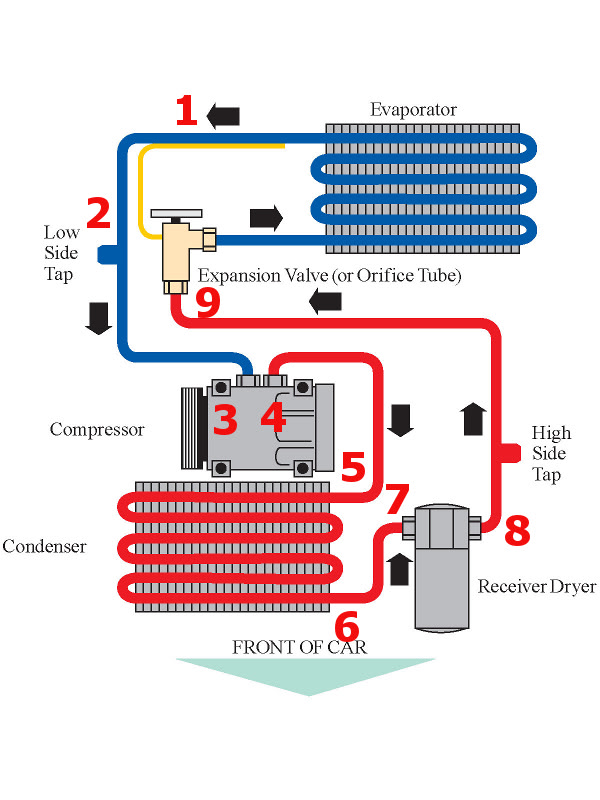

AC System Identification:Before you build a system of lines it is important to identify and know where its components are located:

Evaporator

Evaporator Ė This is the part inside the cabin of the car underneath the dash on the passenger side. In layman terms this is kindof the reverse of a radiator as your liquid refrigerant being sprayed on the inside of the core creates a Ďcoldí radiator which your blower fan blows air through creating cold air.

Blower fan Ė This isnít on the diagram but since I mentioned it above I thought Iíd talk about it. The blower fan is also almost always located inside the cabin and is always very close to the evaporator. The blower forces air through the evaporator or the heater core depending on your vent selections.

Expansion valve - This valve is generally very close to the evaporator and in some cases is built into the evaporator. Its purpose is to act as a spray nozzle for the high pressure liquid output coming from the drier. The expansion valve restricts flow of the high pressure liquid refrigerant and sprays it inside the evaporator core.

Compressor Ė The compressor is located on and is driven by accessory belts on the engine. After the liquid refrigerant is sprayed into the evaporator, it converts to a gas and is syphoned away by the compressor. It pulls the gaseous refrigerant from the evaporator and compresses it before sending it on to the condenser.

Condenser Ė The condenser is located at the front of the car and is cooled with the combination of the radiator fans and forced air at higher vehicle speeds. The condenser takes the hot high pressure gas from the compressor outlet and cools it. The cooling of the condenser causes the gas to condensate and return to its liquid form.

Drier Ė The drier can be located anywhere between the condenser and the evaporator. It is dual purpose and serves as an oil reservoir as well as a desiccant vessel. The desiccant portion of the drier is where it gets its name and functions by removing the moisture from the refrigerant. This is mostly a 1 time thing as a positively pressurized system should not have moisture leaking in. Therefore the drier simply removes moisture during the first few minutes of operation and once the refrigerant is free of moisture it serves primarily as an oil reservoir.

Service ports Ė The high service port can be located anywhere between the drier and the evaporator. The low service port can be located anywhere between the compressor and the evaporator.

Component Level Considerations / Pre-PlanningThis section is mostly filled with FD specific information Iíve gathered over the years, but while the specifics arenít universal the concepts should help you avoid pitfalls when planning a line set for any car. Youíll need to plan for every area addressed below. If you need a condenser, buy a condenser. If you need a drier, buy a drier. If you need to make a header change to fit your compressor of choice, make the change. If you need to identify your evaporator, identify your evaporator. You get the idea. Address every area below before you start planning your lines and DEFINETELY before you start ordering parts.

Evaporator Ė The FD3 RX7 came with two different evaporators. This had something to do with import taxes on cars coming from the manufacturers with AC being brought into the USA in the 90s. Cars with factory AC got taxed more than cars without AC. What you ended up with is some batches of RX7ís being brought into the USA would have factory AC and others would get retrofitted after they made it through customs. The factory AC vehicles included an evaporator and expansion valve combo I refer to as the Denso Evaporator. The vehicles that got retrofitted after customs included an evaporator and expansion valve combo I refer to as the Mana Evaporator. This is important because the Mana and Denso evaporator inlet and outlets are DIFFERENT. You must pre-plan for this. You must know exactly which evaporator you have in order to purchase the correct fittings.

Now, if you search there will be all kinds of ways people have come up with to identify which evaporator you have. Unfortunately a lot of them arenít 100% accurate. Here 2 inaccurate methods Iíve seen:

1. If your car is a touring it has a Denso evaporator. Whereas if itís a Base/R1/R2 it has a Mana evaporator.

2. You can tell because there are stickers on the outside of the evaporator casing that says Mana or ND (Nippon Denso)

Donít use the methods above. Some people get lucky, but chances are you wonít if you take the easy way out and donít do the proper due diligence.

Here is one method thatís accurate but requires that you either have the full working AC system that you disassembled and kept when you removed the rotary or know the full history of the car:

1. The drierís hardline connection will identify the evaporator. Denso driers have a hardline that has a sight glass built into the block that bolts to the top of the drier. Mana drier hardlines bolt directly to the drier without a sight glass and the sight glass is further down the hardline built in as a coupler fitting.

The only two methods I know of that are sure fire ways of determining which evaporator is as follows:

1. Measure the inlet and outlet ports of the evaporator via a thread pitch tool and a caliper or a set of properly specíd nuts:

M14x1.5 | 9/16x18 inlet and 7/8-14 outlet = Denso

M16x1.5 inlet and M22x1.5 outlet = Mana

2. Remove the evaporator from its enclosure box and take a look at the expansion valve.

Denso if it looks like this:

Mana if it looks like this:

Either way, you must know what evaporator you have and know what youíre dealing with before you can begin planning your lines.

Compressor Ė The compressor is a finicky item to plan for, for two reasons. 1. Youíre dealing with placement in a car it wasnít designed to be in, hence youíll run into clearance issues you wouldnít normally have to deal with AND for that simply fact adapters made especially to fit your compressor may not work. 2. Not all LSX compressors have good aftermarket block/adapters. The CTSV LS3 compressor for example has no aftermarket blocks as of the date this tutorial was written. Here are some FD specific notes Iíve gathered over the years related to the use of GM compressors in FD3 RX7s:

1. LS1 Compressor with rear facing inlet and outlet (inlet/outlet face rear of car). This is 100% supported (with the right headers/exhaust manifold). Just be careful that YOUR engine supports it.

Iíve seen folks trying to throw LS1 compressors on LS3 engines which have a drive pulley offset that is incompatible with LS1 compressors. If youíve got a LS1 compressor and it lines up with

your drive pulley, you can relax for the most part (for the most part because headers also play a role (see below)) because you can build on this.

2. LS2 compressors off of Corvettes and GTOís with side facing inlet/outlet ports (pointing towards the passenger side) are NOT supported. Itís just too fat of a compressor in a very cramped space

and there is no way to get any type of adapter in between the compressor and frame rail without major frame rail modifications (Iíve seen it done and itís not pretty). The good news is that to my

knowledge LS2 accessories and LS1 compressors are interchangeable so the general solution is to replace the compressor/bracket with a LS1 fbody setup.

3. LS3 Compressors with side facing inlet outlet ports (pointing towards the passenger side). These are supported but with some caveats.

a. LS3 SS Compressors are supported 100% as there are aftermarket adapter blocks

b. LS3 CTSV compressors are the caveat. The catch is that there are no aftermarket adapter blocks that I know of that I can buy that are slim enough to fit between the FDís frame rail and the

compressor. The SECOND catch is that you can't just swap out the CTSV compressor for a Camaro SS LS3 compressor or LS1 compressor (non compatible accessory spacing) which sticks you

with the CTSV compressor. Where this leaves us is with the difficult proposition of modifying the stock CTSV adapter lines like keycam and skeltic have done in this thread:

http://www.norotors.com/index.php?topic=19986.15 What this involves is cutting the stock CTSV lines short and tig welding new ĖAN fittings or beadlock fittings on the end of the cut lines. Itís a pain but doable. If youíre willing to do the line

modification legwork you can procced with using this compressor.

*Update* - Per

95 Z28 LS3, here is

a new option that could possibly solve the issue with using a CTSV compressor in a FD. It's a very expensive aftermarket block, but it's low profile and could possibly clear the FD's frame rail.

4. LS7 compressors with side facing inlet and outlet ports (facing passenger side). Same story as the LS2 compressor, because, from what cases Iíve seen, LS7 compressor = LS2 compressor.

Unsupported due to its hefty OD. The good news is that like the LS2 compressor I believe this can be swapped for a LS1 compressor / bracket.

Almost as important as the compressor itself is the items that are nearby and affect the clearance around the compressor. In this case, the big offender is your headers / exhaust manifold:

1. JTR Longtubes / Spoolin longtumes = Most clearance and support pretty much any compressor block.

2. Hooker 8501HKR cast manifold = A tight little config that doesnít really limit the spacing of the compressor. You should be good for any of the compressor blocks I list later.

3. LS3 manifolds = Supported but may require heatshield removal / notching for clearance.

4. 2000-2002 LS1 manifolds = Supported but may require heatshield removal/notching for clearance.

5. 1998 LS1 manifolds = Supported but may require heatshield removal/notching AND the EGR casting ridge may have to be ground down for clearance.

6. Hinson Shorties = NOT supported for LS1 compressors. These dip down directly behind the compressor so that rear facing inlets/outlet have no chance of using an aftermarket block. You can

modify stock lines that includes a more low profile connection to the compressor but thatís outside of the scope of this tutorial.

7. Hinson Longtubes = Supported, but I youíre very limited on your options. The reason being is that youíre stuck using a 90 degree block and 90 degree fittings and itís a ridiculously tight fit

between the compressor fittings and the headers. People have been able to do it by wiggling them in and/or some grinding, but I donít recommend it if you have the option.

Condenser Ė The condenser is a good bit easier to deal with as you donít really have clearance concerns. The only hard part can come in with mounting the condenser since some radiator options (Hinson, Howe, Mishimoto, etc) donít have condenser mounts, so in those cases you have to fabricate some type of mounting system for your condenser. When mounting any condenser you will face an orientation decision. Your choice will be to either mount the condenser with the smaller port high (closest to hood) and the larger port low (closest to ground) or the large port high and the small port low. I used to build all my lines with the condenser orientation = small port high, large port low. This created some easier router options and life was good. Since then, I have been advised by someone whose opinion I value that itís better to orient the condenser small port low, large port high. Apparently the condenser functions a tad more efficiently and you run less of a chance of liquid refrigerant backing up in the lines to the compressor. In my example builds shown in the posts below, youíll see most of them oriented small port high, large port low. For the purposes of this tutorial I would advise you orient the condenser with the small port low and the large port high. My examples will still be useful, but make a mental note that youíll need to shorten and extend 2 hoses so you can accommodate the new orientation of the condenser.

Apart from sizing the condenser to your radiator, the only thing you really have to worry about getting right is that the inlets and outlets are something you can work with. Almost every universal / aftermarket condenser Iíve dealt with comes with #6 and #8 male beadlock fittings. More exactly, #6 = 5/8Ē Ė 18 male beadlock and #8 = 3/4Ē Ė 16 male beadlock. Try and get a condenser that conforms to these standards (shouldnít be hard) and avoid flare fittings, or proprietary mating system.

Now for FD Specific condenser options you have.

1. Sambergís Radiator with CAI. This is simple, just use the condenser he recommends and it will bolt right up:

http://www.ebay.com/itm/Universal-A-C-Condenser/140277905793?_trksid=p3286.m20.l1116&item=140277905793&pt=Motors_Car_Truck_Parts_Accessories&vxp=mtr2. Other. Youíll have to measure your radiatorís core surface area and shop to find a condenser that will take advantage of the area. For example, a LS swap specific Mishimoto radiator has core

dimensions = 22.2Ē x 15.75Ē so youíd probably want to shop around for a 22x15Ē condenser if you can find it. To do that, just ebay/google ďCondenser 22x15Ē and see what you come up with. Iíll

go ahead and tell you, you wonít find a 22x15Ē condenser, but 22x14Ē is readily available for < $50 and would be a solid choice for a Mishimoto radiator. All you have to do when you get it is

figure out how to mount it to the front of your radiator. This is usually done by getting your local welder / radiator shop to weld tabs on the front of your radiator. Perhaps down the road this

thread will fill up with specs of condensers they chose for radiator XYZ but for now youíll have to do it case-by-case.

Drier Ė Home stretch! This one is easy I promise! For your drier I would suggest using a 4Seasons 33562. You can get these off of rockauto for $15! Itís an OEM item for older Jeeps and as such is something thatís very easy to find and dirt cheap. Itís sized to be just right for 80s and 90s sports cars. Itís got a built in bracket so itís fairly easy to mount. Additionally, it has a sight glass built into the connection block above the reservoir. It also has very standard #6, 5/8Ē Ė 18 male beadlock fittings for the inlet and outlet. Finally, it has a M10 shrader valve connection which is what the stock GM LS1 pressure sensor adapts to, and what I spec for people to use when designing a LSX controller.

The only difficult part may come in place when mounting it. Ideally, with a LHD USDM spec RX7 youíll want to mount it on the passenger side of the engine bay between the condenser and the evaporator ports. When I build my kits, this generally boiled down to me mounting the drier to the frame rail right around where the heater inlet/outlet ports are on the LSX engine. The only other point I had to address is that with some radiators, the inlet hose to the radiator crowds the area down by the frame rail making it necessary to raise the drier above it. I generally accomplished this by using a 2Ē spacer and a 70mm M6 screw to float the drier above the frame rail. Youíll see this reflected in my designs below.

One note Iíll make about the drier while I have the floor is that it will be delivered with caps sealing the inlet and outlet. The caps are there to trap nitrogen which is inside the drier. The nitrogen keeps the vessel pressurized which keeps moisture out. When you remove the caps and the nitrogen comes out, regular air and humidity can get inside the drier and eventually saturate the desiccant. This is bad. This can be avoided by keeping the caps in place until you are ready to actually hook up your lines. You can mock up your drier and do whatever with it. Just donít remove the caps until youíre ready to install the lines and charge the system

Control Ė Youíve wired your car with some type of compressor control system havenít you? If not, donít worry, Iíve got two more tutorials that can help you:

Ultimate LSX AC Control Tutorial - HalfSpec EngineeringUltimate LS1 AC Control Tutorial - HalfSpec EngineeringSo thatís the component section. Really, thatís the hardest part. Once you get the components of the system settled, the rest is simply getting your fittings sorted out, measuring for your lines then crimping everything together.

Fittings, Seals, and Tools:These are the most common fittings, adapters, seals, and blocks I kept in my inventory when building LSX FD3 AC lines and what I used them for.

Tools:

Tools:To crimp AC lines you need a crimper. I own a Mastercool 71550 which is about the least expensive fitting crimper you can get:

Its survived 4 years of hard use as Iíve used it to build ~ 75 sets of lines. Definitely worth the money.

I also own the following Tekton 6466 PVC cutter:

Technically itís made to cut through PVC, but it cuts through AC hose like butter so itís a favorite of mine for getting clean straight cuts.

Youíll also want the following:

1. Vice grips (to hold onto the crimper)

2. Socket set / Impact Gun + 19mm socket

3. Yard Stick

4. Wax Pencil or other marker than can mark on black rubber hose

5. Beers