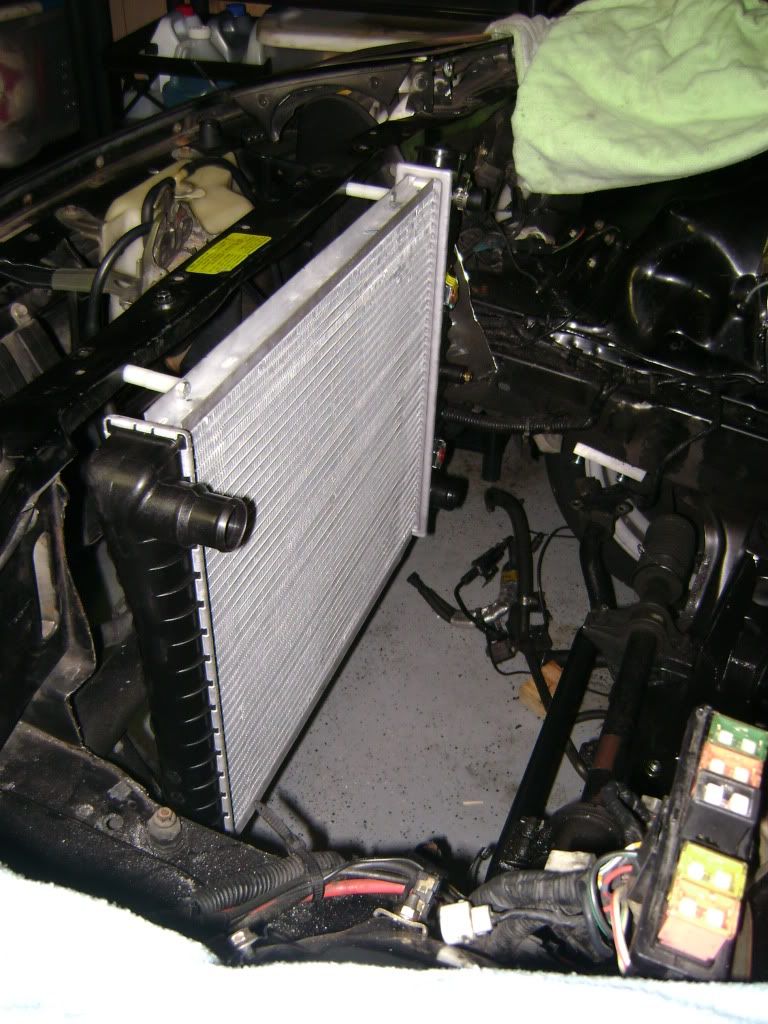

While I am waiting for my Russell fitting I decided I would go ahead and work on the radiator, which was nice to work on with the engine out of the way. I decided to go with the Monte Carlo Radiator. It was a bit smaller than the C4 corvette but did not require 'massaging' the frame rails.

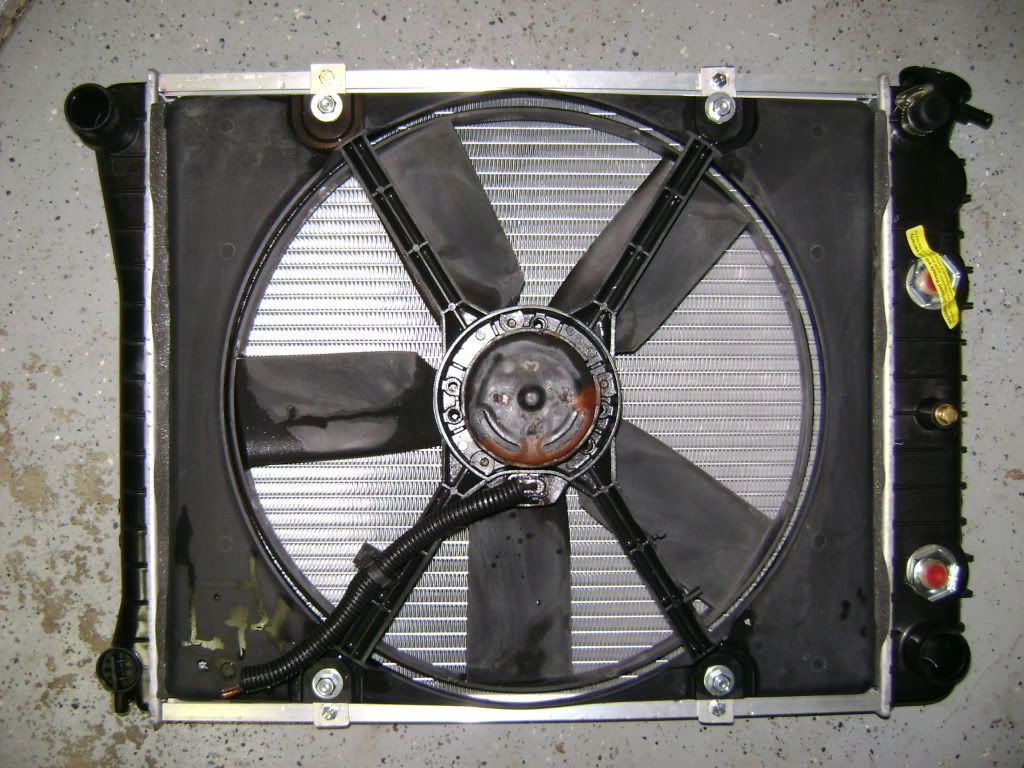

I played around with two different fan options I found the Ford Taurus 3.0 V6 fan at the junk yard. The only reason I got it is I didn't realize the popular Taurus fan is for a 3.8 V6. Either way it seems to be a very similar design. The other fan idea I got from Antirotor, turned out to be a Fiero Fan.

This pic shows the Fiero fan is slimmer than the Taurus fan.

Did some cutting, you'll see once you try to fit a radiator...what has to go and what can stay. Nom nom.

Taurus Fan

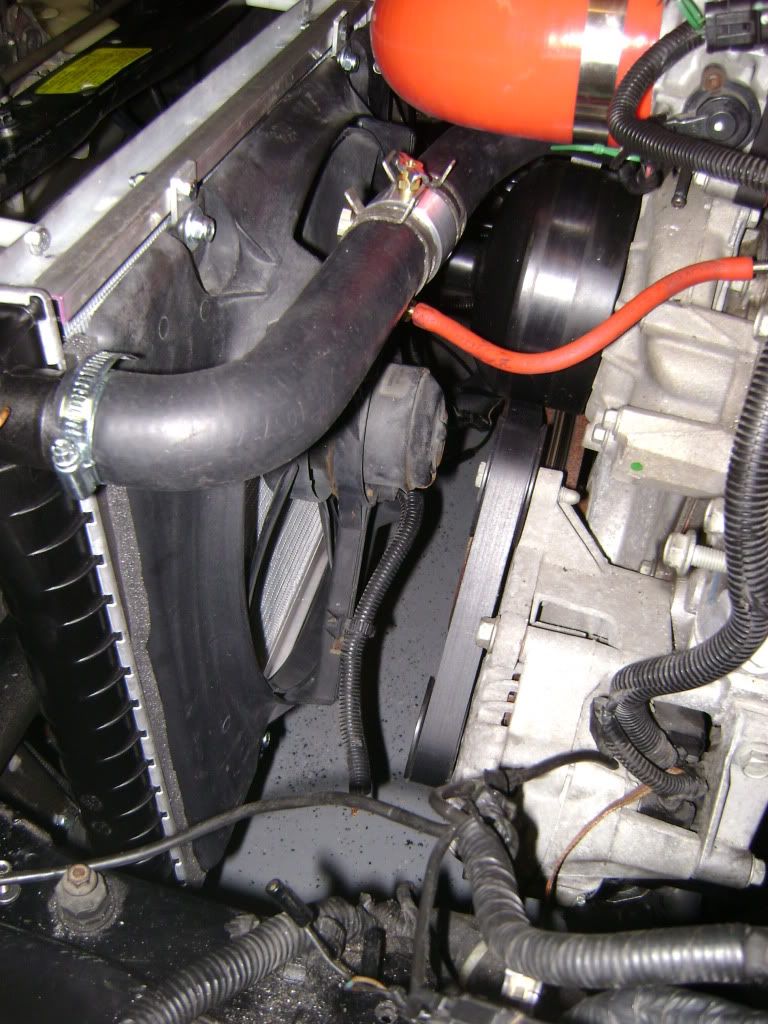

Fiero Fan, fits MUCH nicer.

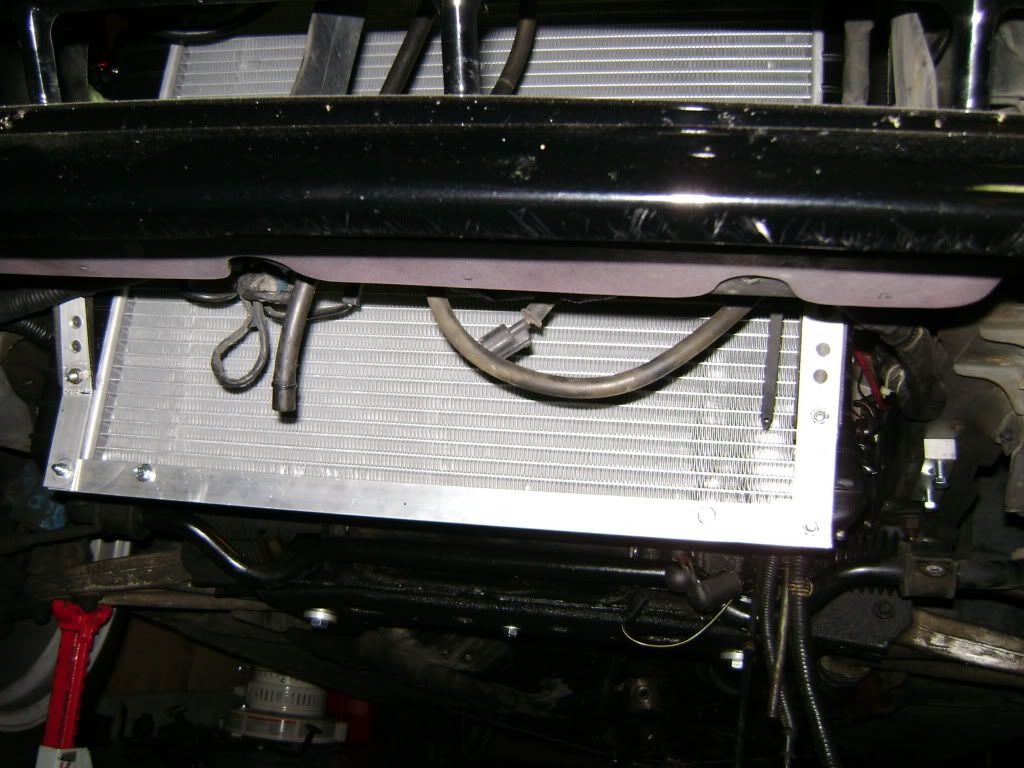

Used some aluminum U-chanel for the top and bottom fan mounting. the U-channel helps seal the top and bottom of the fan while also spacing it out from the radiator some to help with the wind velocity profile.

Used some foam sealer from Lowes to seal the sides.

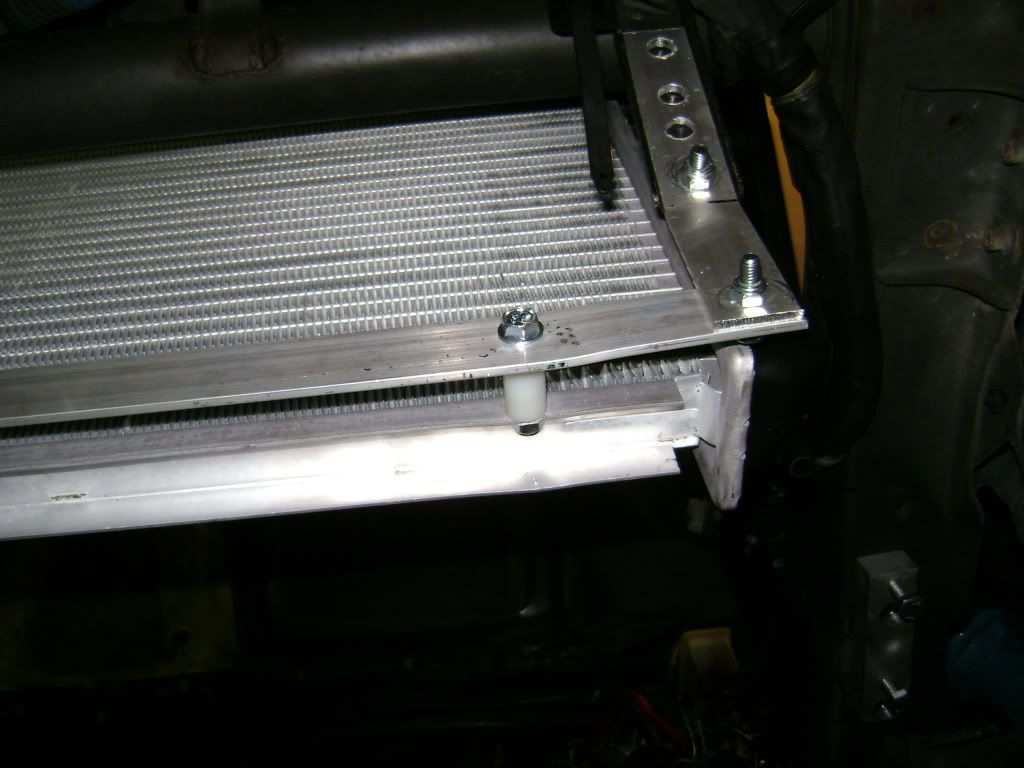

Here are some pics of the Mounting hardware I made

The bottom of the radiator is actually the same level or a bit higher than the subframe.

I have had the car running with this set up (use the PCM to control the fan) and have not had any over heating issues. I am very pleased.

For the hoses it is very Simple. The bottom hose I was able to use the STOCK top hose for the RX-7 radiator. It makes a great 1 piece lower hose! (I like free stuff!)

I went ahead and ordered this steam vent from Jagsthatrun. its a bit pricey I think $50 with the sight glass but I feel that it was well worth it. Being that this radiator does not have provisions for a coolant level warning/sensor the site glass is crucial in making sure that you don't have an air pocket in the system. A lot of people have problems with getting air out of the cooling system so it just wasn't worth the risk. Fortunately I have not had any major issues with filling. I just Undo the top hose at the radiator and fill the hose and put it back on the radiator. Then I just bleed the system with the JTR steam vent and it does the trick very well (by getting the engine to operating temp).

In my parts list you can see the part number for a seamless upper hose, the only reason I cut mine was to put in the steam vent. Thanks to antirotor for finding a good top hose for the monte carlo radiator!!