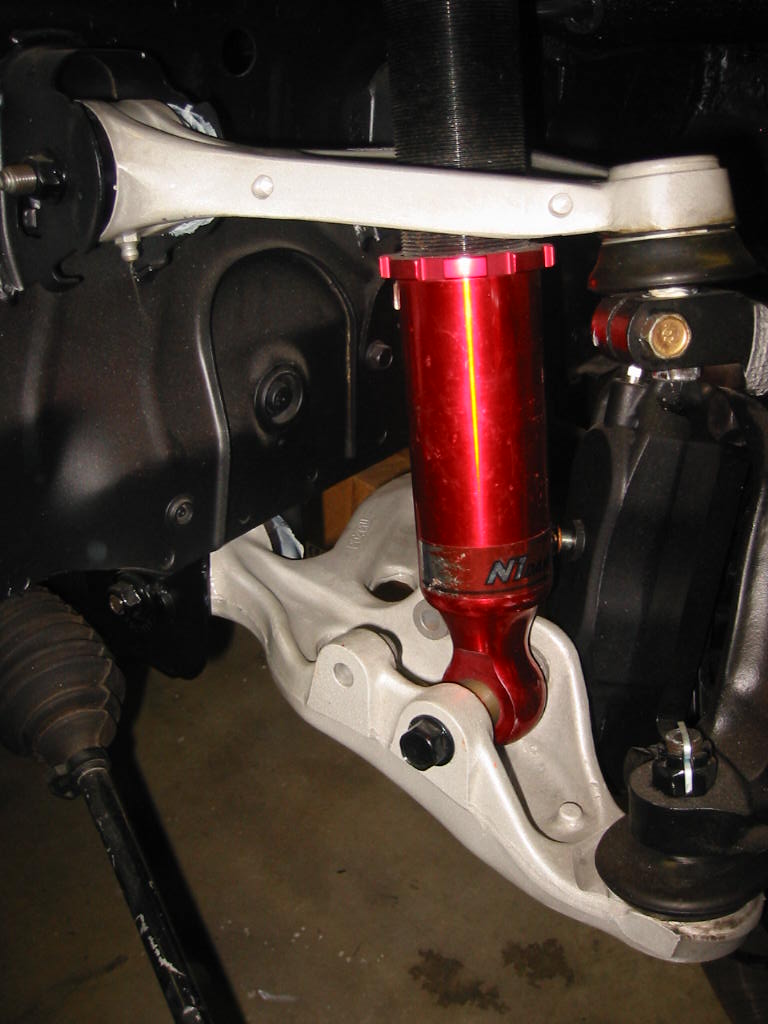

Coil over suspensionAs mentioned before in the weight section I went with the Zeal setup after trialing a couple different types of coilovers. The Zeal setup best fit my requirements for light weight, great ride quality, excellent build quality and adjustability. They also avoid the use of a pillowball top pivot that wears quickly, transmits a ton of noise and vibration, and offers no real performance benefit.

Bushings

Bushings When I first got this car from the previous owner he had mentioned having the rear end clunk that is typical on higher mileage FD?s. I got a full set of pillow ball bushing replacements and seals from Ray at Malloy Mazda, and began searching for a set of Jimlab?s unobtanium bushings. As is typical for me I got a set off the club at a smoking deal, after a too zealous owner realized they would never undertake the suspension bushing job. At this point they were still the only option to replace the stock rubber bushings. I figured I should install them over a weekend while I was home from an internship. Not a good idea. IIRC it was raining, and I was working on the driveway in late December. I later got pretty sick from the long hours in the cold and wet. I learned that stress is not a helpful factor when working on my car. After the install I only drove the car about 2 miles. It felt great, and even with the ~400rwhp that it was putting out, it felt like quite a handful ? more than enough for a driver of my caliber. So I went home and tore it back apart to create a true monster?.

As the months (more like a year) progressed the polyurethane bushings from superpro became a reality. As this new option turned up more and more unobtanium users found their voice and griped about the ride quality of their bushings. Then I also saw the results some of the guys were posting of their control arms after their suspension rebuilds. They would bead blast the suspension parts, then throw on some clear coat. It looked as good as it handled, and I wished I had taken the time to get as nice a result. I considered what my final goals were for my car, and realized I wanted a ?street? car that could hit the track, rather than the converse. The sacrifice of Noise and vibration was a real factor to consider with the nylon (or delrin) style bushings.

Then came the day when the superpro bushings were on super-closeout-special-one-time-only-buy-it-now-holy-$hi7-what-a-deal pricing, and the straw broke the camel?s back. I bought a set. In the following months I had my suspension parts sandblasted locally. Of course the guys ruined all my wheel bearings and rubber boots in the process. Then I got the pleasure of replacing rear wheel bearings on a FD. (If anyone needs any pointers I have done ~4 or 5 at this point.) I was unfamiliar with how much prep would be required of me vs. what the blaster would take care of. The end lesson is to count on the fact that the shop doing something for you will screw up anything you don?t specifically prevent.

Since then I bought my own sandblasting cabinet?

Now the parts looked brand new, but the sandblasting process leaves a bare aluminum finish that quickly absorbs all that touches it. I knew my efforts would be wasted quickly without a finish on the arms. I originally thought about powder coating the parts, but there are several bearings and ball joints that I was concerned about damaging if I exposed them to the ~400 degrees required for curing powder coat. After a bit of research I decided to coat my suspension parts with glisten PC from POR-15 and reinstalled the (now polyurethane) bushings. To help with the budget I was able to sell my unobtanium bushings back on the forum, obviously at a bit of a loss, but it made the pain a bit more bearable.

Oh, and since my Harbor Freight press and I got to be very close during these bushing/bearing swaps I thought I would include a post I made about using the thing for this job:

Did you break the press or one of the arbor plates? I actually cracked one of the cast iron plates and one of the sockets I was using went ricocheting off the wall.

Always stand to the side of the press when applying pressure so at least the frame of the press is between you and any potential flying objects.

No kidding! I got about 20 or so gouges in my concrete near where I did my bushing job from blowing apart the fixtures of arbor plates, steel rods, harbor freight presses, and suspension arms/bushings.

When we replaced Dan's rear wheel bearing last month we had a helluva time removing the axle from the spindle splines. After mounting it in the press we tried a number of times to remove it. Finally just pumping the press from "damn that's a ton of pressure" to "$h!t everyone stand back" to finally "well lets see what breaks first" before "BOOM!" then we all stand around checking our limbs before we see the axle popped free, sending parts everywhere. Then the celebration begins for integrity of biological systems, and their triumph over mechanical demons...

Honestly the bushing job is waaaayyyy more of bitch than many think. I damaged one of my front control arms when the socket I was using to press the bushing bound and gouged the side. Be really careful, I half expected to see that someone had taken off a finger/arm/other appendage doing this job. When those suckers let go with that kind of force behind them, it sounds like gunshots! My concrete garage floor still is gouged from the resultant projectiles from my bushing swap!

Torsional rigidity: The stock torsional rigidity of the FD is ~15,000 Nm/deg. The Ancas book says that the FD has 20% greater rigidity than the FC (I guess that puts the FC ~12,000 Nm/deg?). But the Rx-8 is supposed to have 30,000 Nm/deg! (It basically has an I-beam running down the center of the car) Shit! Time to get this thing stiffer (I know, I know That?s what she said).

I wanted to improve the torsional rigidity in order to increase responsiveness, and reduce deflection under the higher strains I plan to put the car through. I saw a couple options:

Braces You can buy braces to and from most anything in FD?s. Some may help a bit, others may not. Accurate data on how much any of them help is a unicorn. All cost money, and all add weight, so I figured I would go with whatever seems to offer the most help, and the least weight in my budget.

Front ? Cusco makes a titanium bar that is insanely light (wait hold on I?ll go weigh it? ) and I found a guy in a pinch looking to get rid of his. IIRC I got it for 150 shipped. Also it has the same general shape as the eBay front bar a lot of the guys got to fit with their swaps.

In the future I may have it made into a 3 point unit, or add on an additional unit that ties to the fender wall such as this piece:

[Almost went with the autoexe front gymnasium, but it weighs in at 6 lbs or more, no guarantee it would fit, and costs a ton of $. Not to mention a lack of any data on how much better it would work.]

Rear ? Cusco makes a CF rear brace, and once again I found a deal and had to have it. It has triangulated aluminum braces to the floor of the trunk as well. They come polished, but I powder coated them to fulfill requirement #5. Ya need to drill 2 holes in the floor of your trunk, but after what I did to my trunk it was no biggie.

Fender ?Nagisa makes a fender brace, that has had some good reviews. Since my fenders are off anyway it won?t be too much of a bear to install these. The set of 2 weighs in at 5 lbs. Also they are of steel construction, which was a bit of a surprise to me.

Undercar ? I realized I would not be able to do a lot of these until I finish the exhaust as clearance is critical, and space is a premium down there. I imagine there will have to be some custom stuff made up, as existing braces are made for the rotary sub frame/stock driveline/exhaust.

* FWIW I do not know how much the removal of the stock PPF reduces the torsional rigidity of the FD, if at all. The possible concern is the removal of the rear cross member of the front PPF that we replace when making our ls1 subframes. I feel that the thicker gauge metal we use helps, but don?t know if it matches the rigidity stock setup.

I do plan to create an undercar brace that supports either side of the trans tunnel somewhere near the front to account for the elimination of that rear bar.

Structural foam in the frame:So I was looking for a way to stiffen the chassis, but was having difficulty with the decision to step up to a full cage. What I came across was a bit of a cheat that Ford uses to stiffen up their truck chassis, and also keep things quieter.

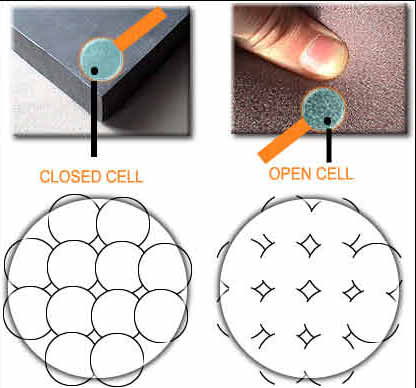

This stuff is not to be confused with the open cell stuff you can find at your local hardware store. It is far more dense when compared to most open cell foams, so it does a better job of supporting the chassis. Also It is chemically cured, so that it will fully cure in your frame rail unlike the oxygen cured open cell stuff that cannot cure fully without exposure to air. Finally closed cell foam's components are sealed from one another. This prevents water from seeping into the foam as it sits in your frame rails, and being held there, effectively rusting your vehicle from the inside-out.

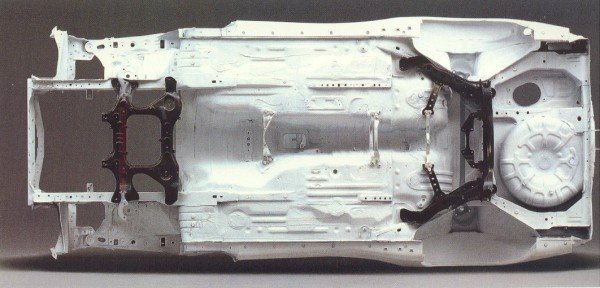

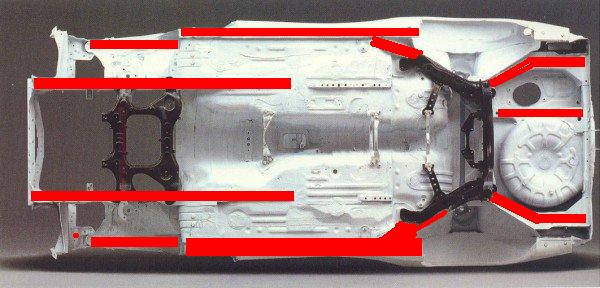

When applied to the hollow members of the uni-body on the rx7 they will better resist deformation, while at the same time reducing vibration and noise. I ended up filling the members that seemed structural as I examined my car, and various diagrams in the FSM. This took quite a bit of time, and I cannot yet say what the final result offers. In fact I don?t imagine I will ever get more than subjective results, but time will tell. Here?s more of the background.

Here are a couple underside pictures that show the members I filled with closed cell foam:

I hate to do it but I will quote SCC:

?Structural foam, in the 2 lb per cubic foot density that we used, can stiffen chassis members up to 40 percent.?

This is from their project 300zx:

SCC article on Foam in the chassis Hey 40% stiffer sounds good. Better yet, it adds little weight vs. most options that offer similar results.

I know what you are thinking:

Q: ?Hey Mike, why not a cage? ?

A: I did not go with a cage for several reasons;

#1 I needed to draw a line between street car and race car, and IMO it is not a street car with a cage. I didn?t want to be dancing around a cage during ingress/egress, and the interior in the FD is already pretty tight (or maybe I am too big). Since I plan on driving mostly on the street, I did not want to live with the compromises of a cage.

#2 there is the question of safety. While on a track a cage improves safety and rigidity, but it?s a different story on the street. On the street a cage is usually used without race gear such as a helmet or 5 point harness. This opens the opportunity for soft squishy human to interact intimately with hard metal bar in the event of severe jostling (i.e. an accident). Factory engineering spends a great deal of time preventing this sort of interaction from occurring in a variety of accident types. I did not want to toss that out the window in order to run a custom cage. For this reason I believe a cage is more a greater liability than not having one on a street car.

#3 The best and most effective cages are custom and welded in, which means adding a bunch of weight not to mention cost. Even chromo cages often eclipse 100 lbs, and as you saw with goal #1 I worked pretty hard to shave ~100lbs.

#4 There is the risk you run by involving another ?professional? to fab your cage. Finding the appropriate individual locally can be a daunting task. Afterwards your cage is only as good as their engineering and skill. Add to this the ease with which your car can be damaged, or otherwise devalued as you leave it with said individual.

Braking The astute reader (or viewer) would already know that I upgraded to the Racingbrake BBK front and rear partially for the weight savings. But the biggest reason I upgraded to their kit is to have improved thermal capacity of the larger rotors. Other strengths of this kit are the improved brake cooling due to the design of the rotors, balance front and rear braking with the retention of the stock parking brake, and finally the economic price point of this kit (especially on the initial fitment group buy).

[Warning, potential flame material here]

[Warning, potential flame material here]Also I have removed my ABS, which lost some additional weight as well. Now I am not Michael Schumacher, nor do I claim outstanding driving ability. But over the years I have gathered some corroborating info that tipped the scales for me in that decision.

-If running different diameter tires from the stock setup, the calculations the Mazda abs system uses to determine spin are thrown off, and the braking becomes substantially worse than stock. My tires are far from the stock size.

-The stock system is pretty rudimentary in the 93 model year, and has many improvements through the years. Since I had a 93 setup, I was not too sad to ditch it.

- The stock system is notorious for leaks and various failures. I figured I would eliminate the potential for problems down the road. Sticking to the KISS is one of the doctrines I swear by in my vehicle builds.

- In the 5 years I had my rotary powered FD on the street I never once got into the ABS. In fact I actually considered that the ABS may have never worked before I sold it. So I took it out on a rainy day, and railed hard on the brakes, sure enough they pulsated as an ABS system is designed to. Even with the hawk HPS pads I had on for 3 years I never got into the brakes enough to trigger the abs, until the day I actively tried to. This is not to say that someday I may regret this decision, but the chances are minimal in my mind.

- If I was planning on actively tracking the car and frequently using maximum threshold braking I may re-consider. But for the time being I believe that my setup when properly adjusted will work well for a predominantly street driven vehicle.

929 Brake MC I know that a lot of guys go with the 929 master for the older FD big brake kits. It apparently gives much better pedal feel for the larger calipers. I have mine installed for my FD, but have not driven it yet, so I can't give you any impressions.

But I do expect to have more confident braking due to it, albeit with more pedal effort.

On the FD it flips the side that one of the lines mounts to, which requires a new line. Since I removed the ABS as well I had to do a prop valve, and while I was at it I replaced all my brake lines.

One of the problems I had with the brake lines was the retention of the factory protective coating. I didn?t want to lose the protection, but it quickly bent and looked like crap after changing any bends in the line. Here is the solution I came up with:

1. Form the line into the shape I needed (I know duh)

2. Slicing the side of a silicone or rubber vacuum line to the length desired for protection

3. Slide the hose over the brake line, and position to minimize the gap between sliced hose edges.

4. Take a length of heat shrink and place over the entire length of hose

5. Apply heat to the shrink, and celebrate

6. Curse if you messed anything up

7. Question your sanity after spending WAY too much time on your brake lines

8. Have a beer to forget about steps 6 &7

Here?s a picture or two:

Brake proportioning valve:

What a prop valve essentially does is reduce the line pressure in the brake system for the rear brakes. This is done due to the natural tendency for the rear brakes to lock before the front when the weight of the vehicle shifts forward under hard braking. Stock brake systems have this set for the stock components. Since I altered the stock setup quite a bit, I needed to add an adjustable valve to maximize braking with my setup. I also gain the ability to dial in my brakes for a variety of conditions.

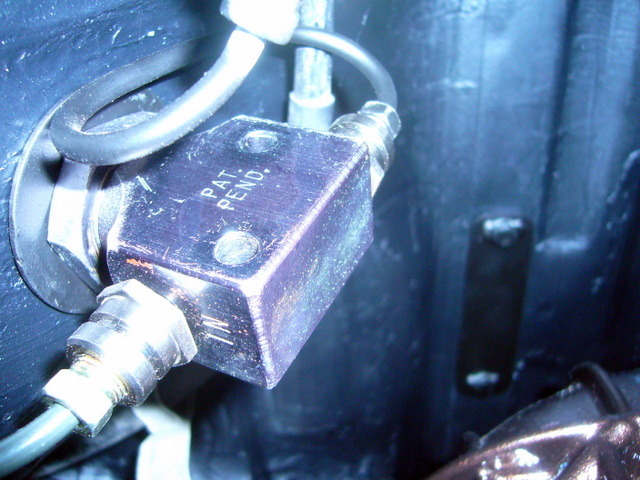

There are a couple different aftermarket prop valves. Most are a screw-type, some are a lever type. Also some have detents and others are more of a continuously variable adjustment. I found it hard to record or measure the adjustment of the latter, so I preferred a detent style for this project. In addition I could only find one that was available with metric brake line fittings. So I went with the Tilton prop valve which I got off EBay for ~20 bucks from a race team. It came with the SAE fittings, which I figured I could just swap with the metric fittings. Urns out the Black valve (what I have) and the Red? Valve (the metric one) are machined differently and the fittings do not swap directly since the metric threaded portion is longer and therefore will not seat. But with a little machining I was able to get the metric fitting to seal, whew!

Here?s what it looks like in the position I chose:

This should be easy enough to access even while driving. Hopefully I will be able to get it dialed in faster this way, and adjust if needed for conditions.

Manual steering As was previously mentioned I went with manual steering for the improved road feel, weight savings as well as simplification. While I had no problems with 285 front tires, the 315?s I plan to run now may make things a bit tougher, so time will tell. Currently it is the Maval unit I plan on running:

But I am also strongly considering that AtomicRex unit.

I would like a couple more reviews and info on this unit. Also I would like to take some bump steer measurements, and decide what height I can raise my rack under my canton oil pan. Then I may have the lower solid AtomicRex mounts machined thicker to accomplish this raise. This resolves the bump steer issue in two ways. First I drop the overall rack less, and therefore need less of an outer bump steer spacer. Second it allows mew to avoid the issues that others have dealt with when using the inner bump steer kit.

Wheels & Tires Wheels and tires are kinda a big deal. After all they are the only thing holding my car to the ground. If you go too nuts, they become a huge deal. So that is what I did?

Guys like kingkyle, and NateTerry went wide with their tires and were doling out shovels of whoop-ass to other supercars on the track.

http://www.youtube.com/v/NmJT6mfTBhUAfter I saw that I figured I needed in on the action. So I traded my 18x10 CCW classics with 285/35r18 Pirellis on all 4 corners for some 18x13 rears, and some 18x11 front CCW c14 corsairs. They drop about 2 lbs per corner over the equivalent size Classics.

For tires I went with Pirelli p-zero rosso tires in a 315/30r18 front and a 335/30r18 rear because of their traction and the tiny bit of weight savings vs. other max traction tires available in these sizes. And the fact that I could get a deal on some low mileage take-offs didn?t hurt either. Also IMO tire compound is more critical to grip than some stretch/bulge, so I considered what kind of driving I do and picked a good max traction street tire.

This jump in wheel and tire size did cost me in the weight department, to the tune of ~55 lbs rotational weight. But I feel the trade-off was worth it for the greater width to my contact patch and corresponding lateral-g?s.

One other aspect to think about for your rear tires is overall tire height. Stock rear tires are 205/55r16?s and have an overall height of 24.9. My new tires are 335/30r18 and end up being 25.9 inches tall. So this is a 4.2% change in overall gearing. The taller the rear tire, the taller your effective gear ratio. I already lowered the diff ratio to 3.55 via the Cobra rear, but the tires I am now running drop that effectively to a 3.413. For my purposes I believe this will be plenty steep for street use and traction after considering the weight of the car and torque I plan on putting out. If I finish off the calculations it looks like I?ll be turning over about 1500 rpms at max legal speeds in 6th. That should allow for some decent mpg.

Oh, and I can?t help but post a link to one of my tire hookup guys, ridiculously low prices, and killer used tires:

Atlantis TireEspecially for fitment, and working out the bugs, it is hard to justify new rubber. I plan on getting some fresh rubber after these bear the brunt of the ?break in? miles?